Hot Water & Steam Water

WHAT ARE WE OFFERING

We will always strive to provide the most effective ways to improve your business performance by optimising your steam system.

We bring a knowledgeable approach to the control and efficient use of steam systems and equipments. By taking the time to understand your business needs, we can create the best solution using our expertise and high quality products and services. Whether your target is to reduce energy consumption and carbon emissions, boost productivity, ensure safe operations or something else, we’ll help you achieve sustainable success.

OUR SCOPE

Provides design and build for :

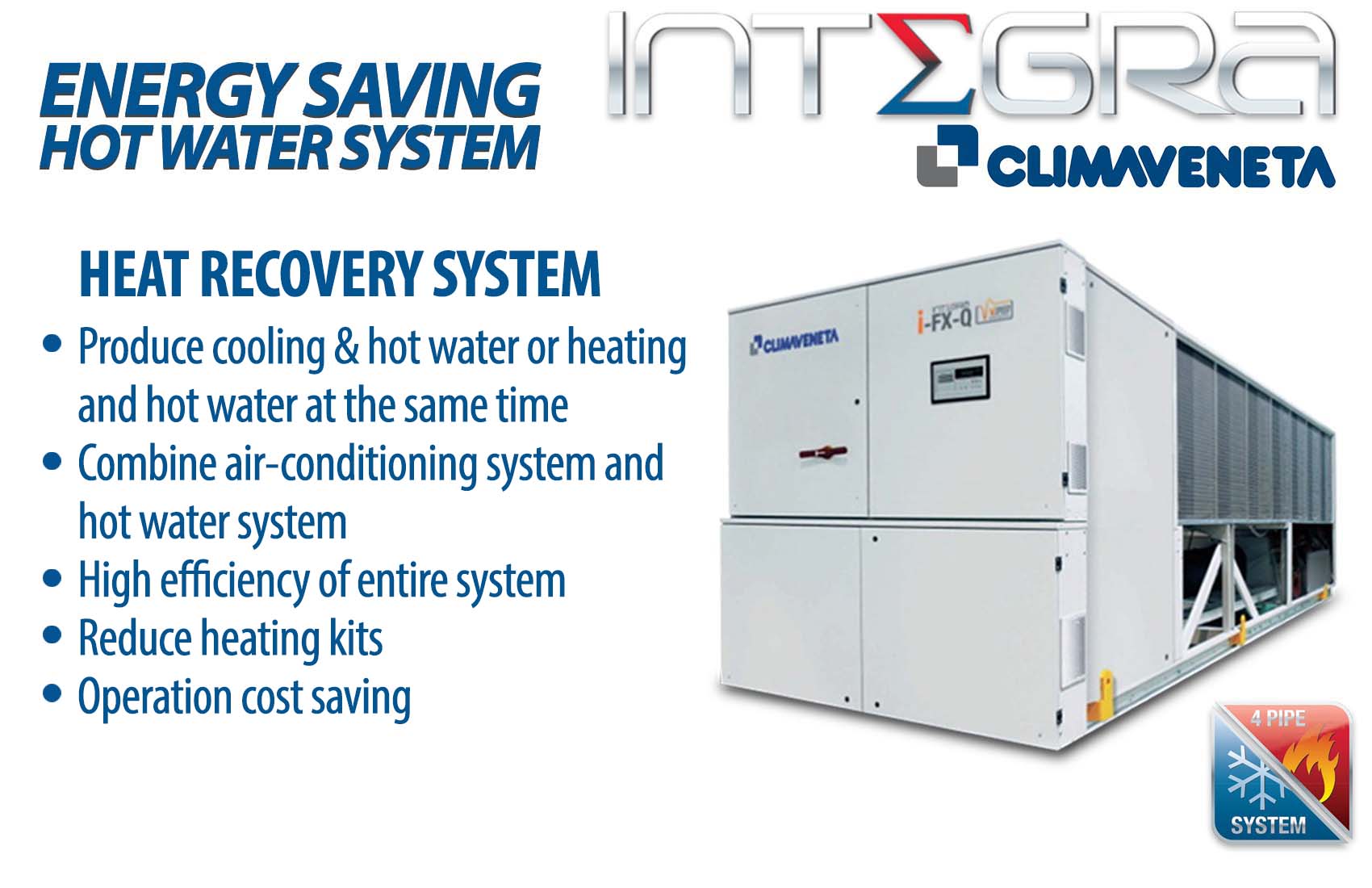

- Hot Water System

Primary System | Secondary - Steam System

Generation Plant | Distribution System | Utilization Condensate | Energy Recovery

Steam, hot water and process heating are all essential resources of many industries. They often provide convenient, reliable and cost effective energy with which to undertake the processes that are fundamental to your business. As such an indispensable tool, there are great benefits to be gained from running these systems at their optimum efficiency, providing the best performance, safety and energy efficiency possible.

Whether you are looking for advice on choosing the right steam trap or building a complete new plant, you can be sure that our flexible steam system services will yield genuine business benefits. Our specialists will work closely with your team to identify, design and implement improvements to your steam system and maintain the resulting efficiency gains.

If you are planning a new steam, hot water or process heating system, this process outlines the steps required to ensure you achieve excellent design and to help you understand where to spend your valuable capital. If your requirements have changed, for example, if there have been significant upgrades to the process plant or equipment, you may need to install more efficient equipment or expand your current system. This will involve elements of both solutions. Firstly, ensure your existing system is running efficiently (Solution 1) and secondly, design the new components of the expanded system (Solution 2). Following this process will ensure that you are not wasting money purchasing more than you actually need. Additionally, information gained from reviewing efficiency may guide the selection and design of the new components of the system.

WHAT IS HOT WATER & STEAM SYSTEM ?

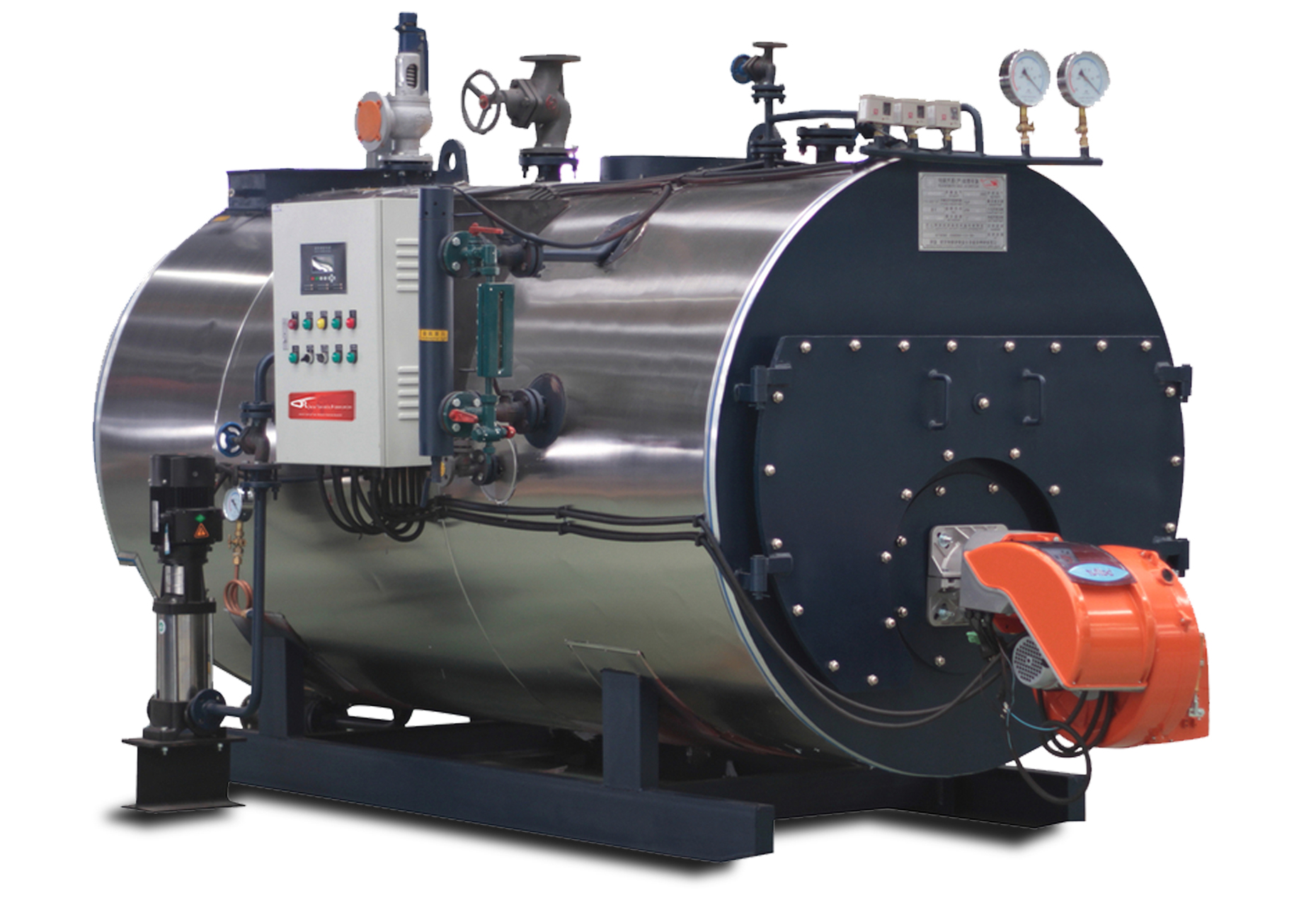

Steam and hot water boilers are defined according to design pressure and operating pressure. Design pressure is the maximum pressure used in the design of the boiler for the purpose of calculating the minimum permissible thickness or physical characteristics of the pressure vessel parts of the boiler.

Typically, the safety valves are set at or below design pressure. Operating pressure is the pressure of the boiler at which it normally operates. The operating pressure usually is maintained at a suitable level below the setting of the pressure relieving valve(s) to prevent their frequent opening during normal operation.

Some steam applications may require superheated steam. It should be noted that superheated steam has a high enthalpy, so there is more energy per pound of steam and higher (drier) steam quality. One example of an application where superheated steam may be required is with a steam turbine. The turbine’s blades require very dry steam because the moisture can destroy the blades. When very high pressure or superheated steam is required, an industrial watertube boiler should be selected.

OUR CLIENTS